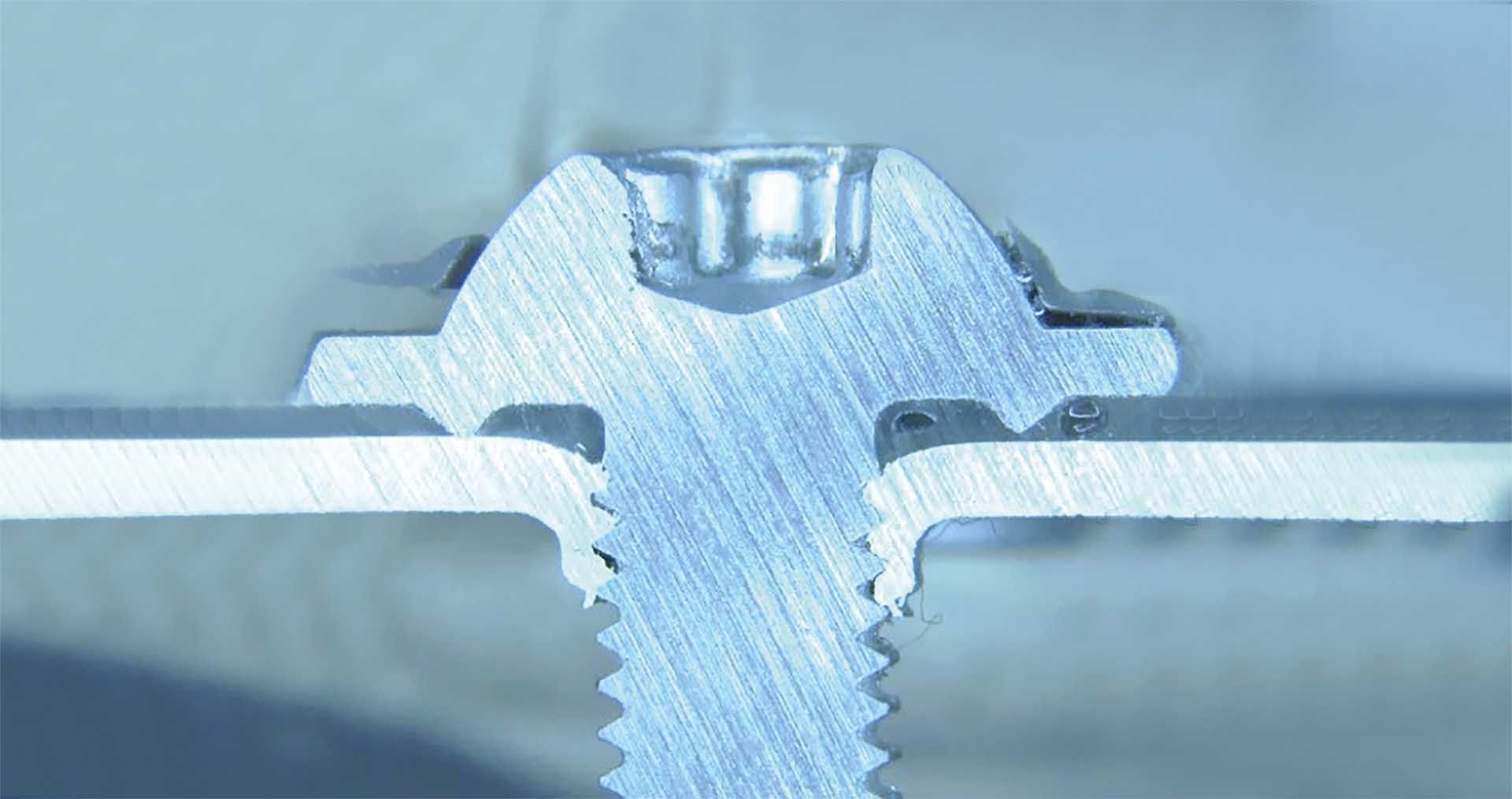

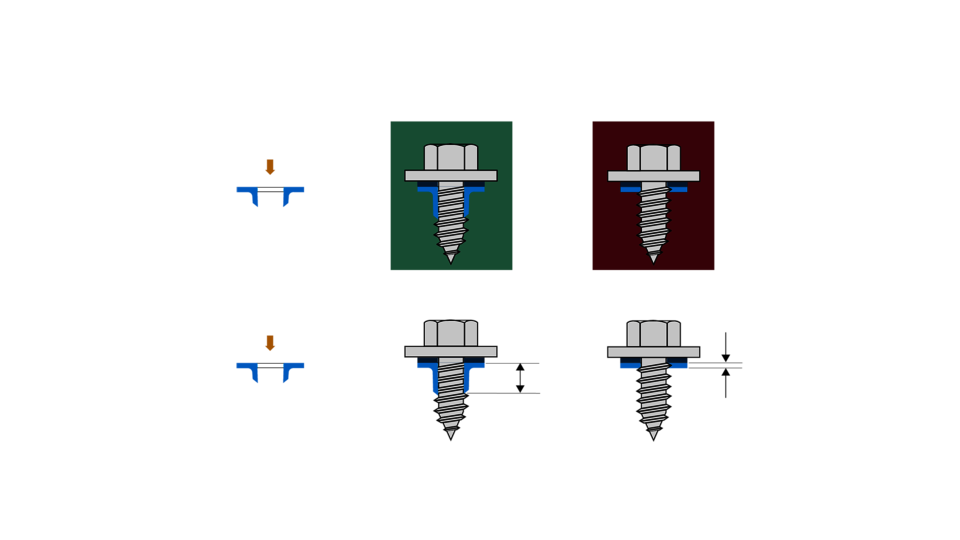

ECKOLD extrusion embossing allows for direct screwing in sheet metal. The embossed structure formed in the process increases the number of turns for the screw and thus enhances its grip. In addition, extrusion embossing allows for higher torques than would be possible with simple screwing of multiple sheets. The technique is suitable for use in virtually all industries where sheet metal is machined and joined, for instance in the production of cars, white goods, escalators or elevators.

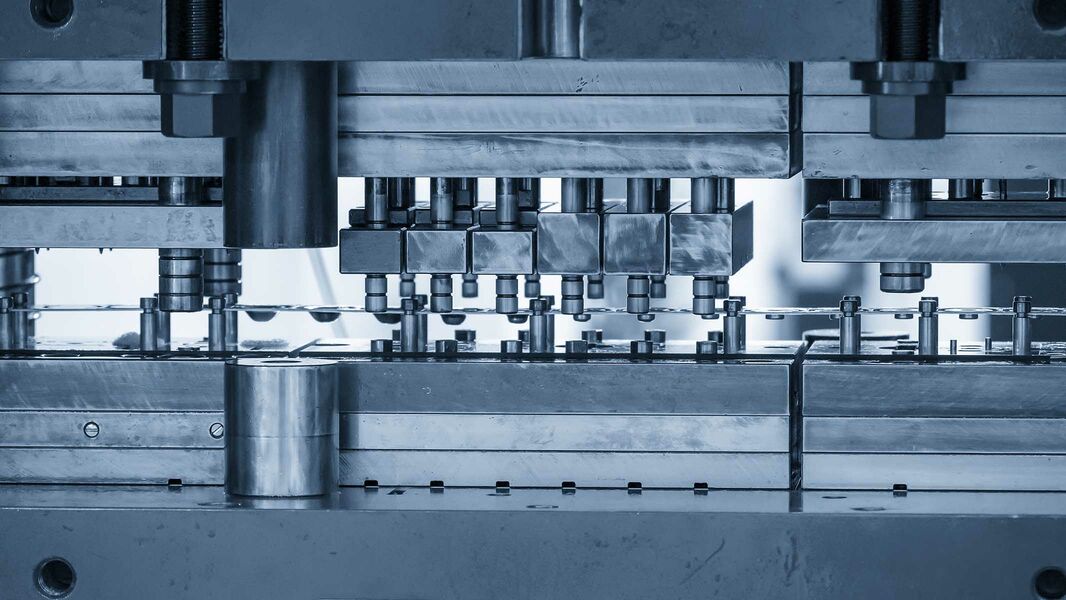

Whether you opt for a stationary, robot-controlled or punch press system – we work with you to devise the best solution for your task. We use for example simulation trials to identify the optimum tool geometry for your project – saving you costs and time! Another advantage of ECKOLD technology is the proprietary ECKOLD VISU software, an innovative solution that constantly monitors all steps of the machining process.

For many decades, ECKOLD has been the reliable partner of leading car manufacturers as well as customers in many other industries where sheet metal is machined. ECKOLD extrusion embossing is an innovative technique for direct screwing, a connecting method that helps reduce investment and operational costs. As extrusion embossing does away with press-fitted or welded nuts, the cost savings can be quite significant. Extrusion embossing reduces the weight of components, which is for instance a key concern in the automotive sector. Our machines for extrusion embossing are of a relatively straight-forward design, reducing the initial capital expenditure. Special control and visualisation software developed by ECKOLD guarantees smooth operation. An intuitive user interface, constant process monitoring and preventive maintenance are only some of the features that bring complete transparency to your production.

Would you like to know more about thread tapping in your industry?

CONTACT US

In addition, ECKOLD offers simulation runs to make sure that the geometry of our extrusion embossing tools is optimised for your specific task.

Other industries

Extrusion embossing can be used in virtually any industry that machines sheet metal. The technique is particularly popular in the automotive sector with both car manufacturers and suppliers. It is also widely used by manufacturers of white goods and household appliances, in the HVAC sector, in steel and metal construction, by producers of escalators and lifts, in aeroplane production and in the computer, lighting and electronics industries.