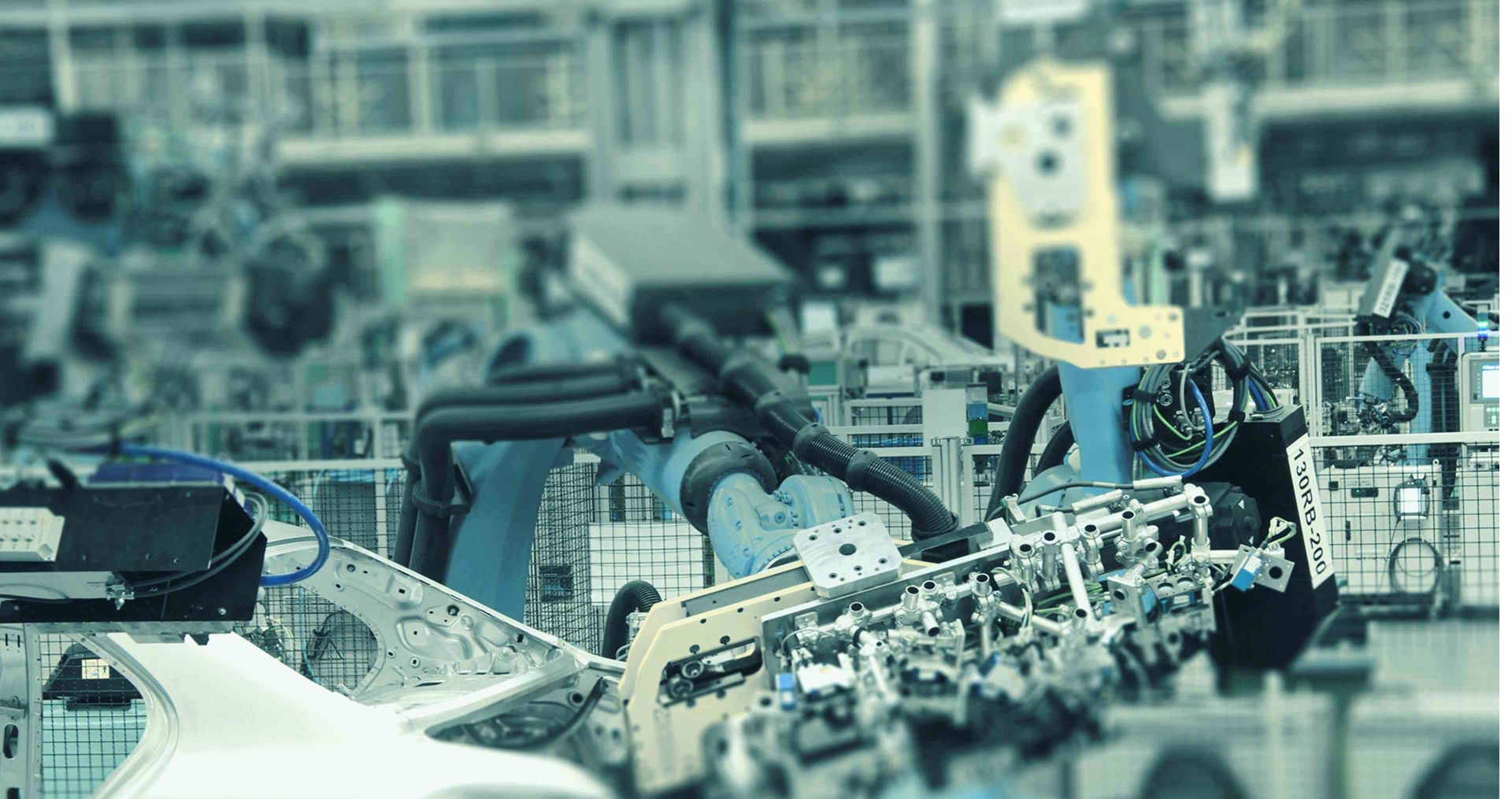

Over the last few years, ECKOLD engineers have been working hard to further improve our machines for embossing punching and dome embossing. Our extremely versatile punching and embossing machines are widely used in the automotive industry where they have become the established technology for efficient and intelligent machining.

Embossing

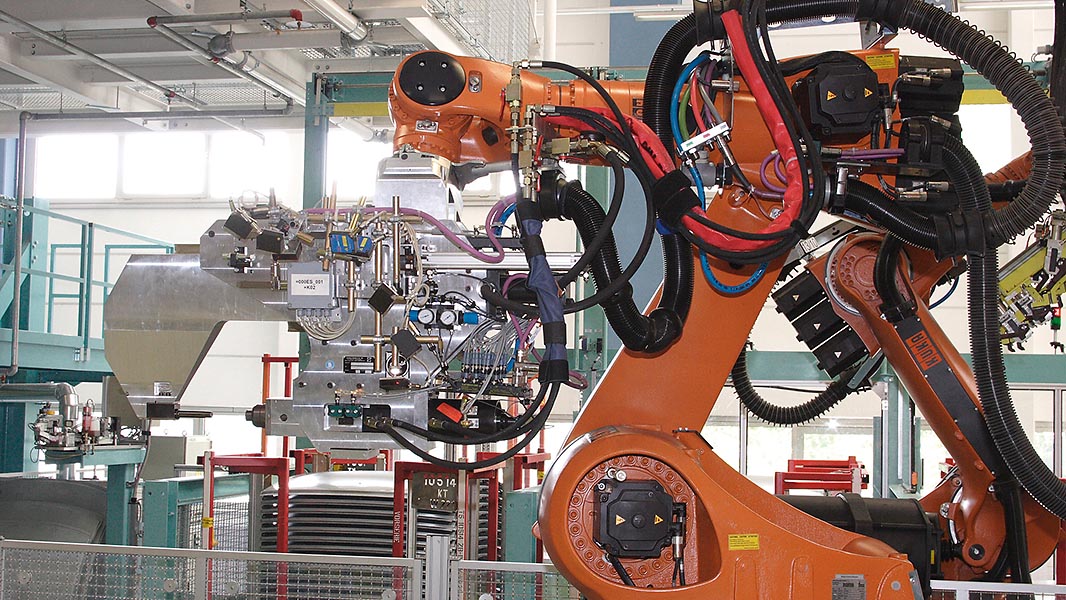

We provide customised solutions for the embossing of studs, numbers and letters (serial numbers, logos, etc.). Our embossing devices come in various designs, for instance in the shape of mobile machines, as components for incorporation into assembly plants or as tools for industrial robot handling. We also design complete embossing plants and machines – tailor-made to suit your applications.

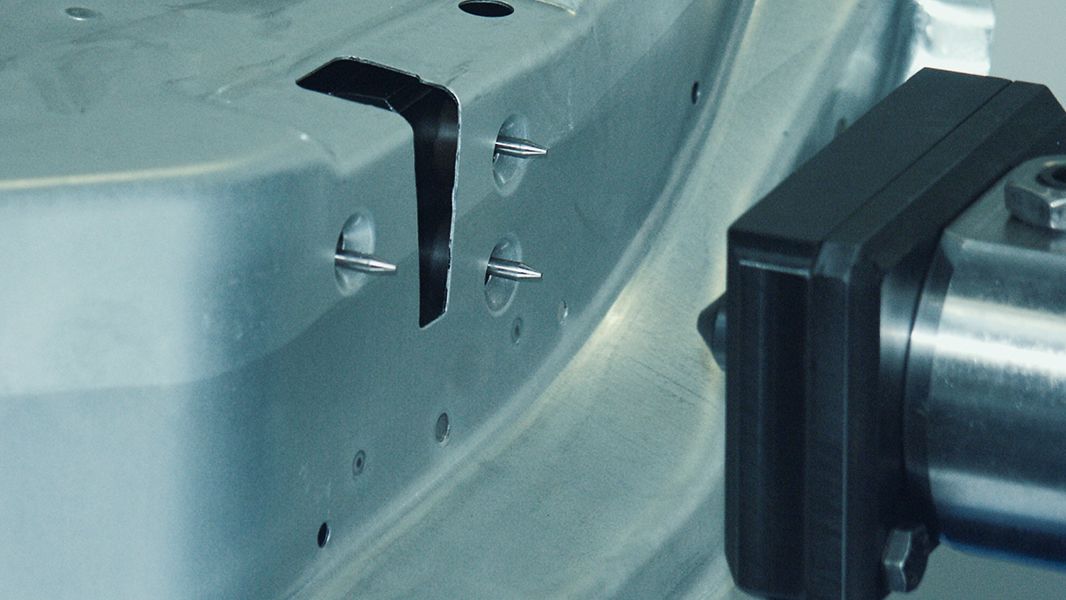

Embossing punching

Embossing punching describes a process where sheet metal elements and profiles are first embossed and then punched in one continuous work stroke. Embossing punching is used so that assembly elements or components can be perfectly aligned to a mating part of different dimensions. Embossing punching reduces cumulative tolerances to a minimum!

Multi-function unit MFG 500/150 E – The machine for every situation.

Clinching, self-piercing riveting, punching, pressing-in and embossing: The MFG 500/150 E is a universal C-shaped stationary machine designed for sheet metal ulilising industries. In respect to working with sheet metal and profiles in aluminium, steel or stainless steel many demands are realized. However a new machine is not needed every time but merely an appropriate tool holder is inserted and the machine is ready for a further task. You can also choose from standardised tool holders or a custom-manufactured tool holder according to your needs. You can find further information in our brochure which is available for downloading below.