Servo motor-driven self-piercing riveting systems for automated production

The applications and features of self-piercing riveting systems are always similar. On the basis of this knowledge we created three standard configuration variants, which fulfil the majority of requirements. Our two servo motor-driven self-piercing riveting systems are designed for stationary or mobile use on a robot. Part variants, complexity, vulnerabilities, maintenance intensity and costs are therefore minimised, which reduces the need for special rivet systems – all for your benefit!

CUSTOMISED SELF-PIERCING RIVET SYSTEMS FOR INDIVIDUAL RIVETING

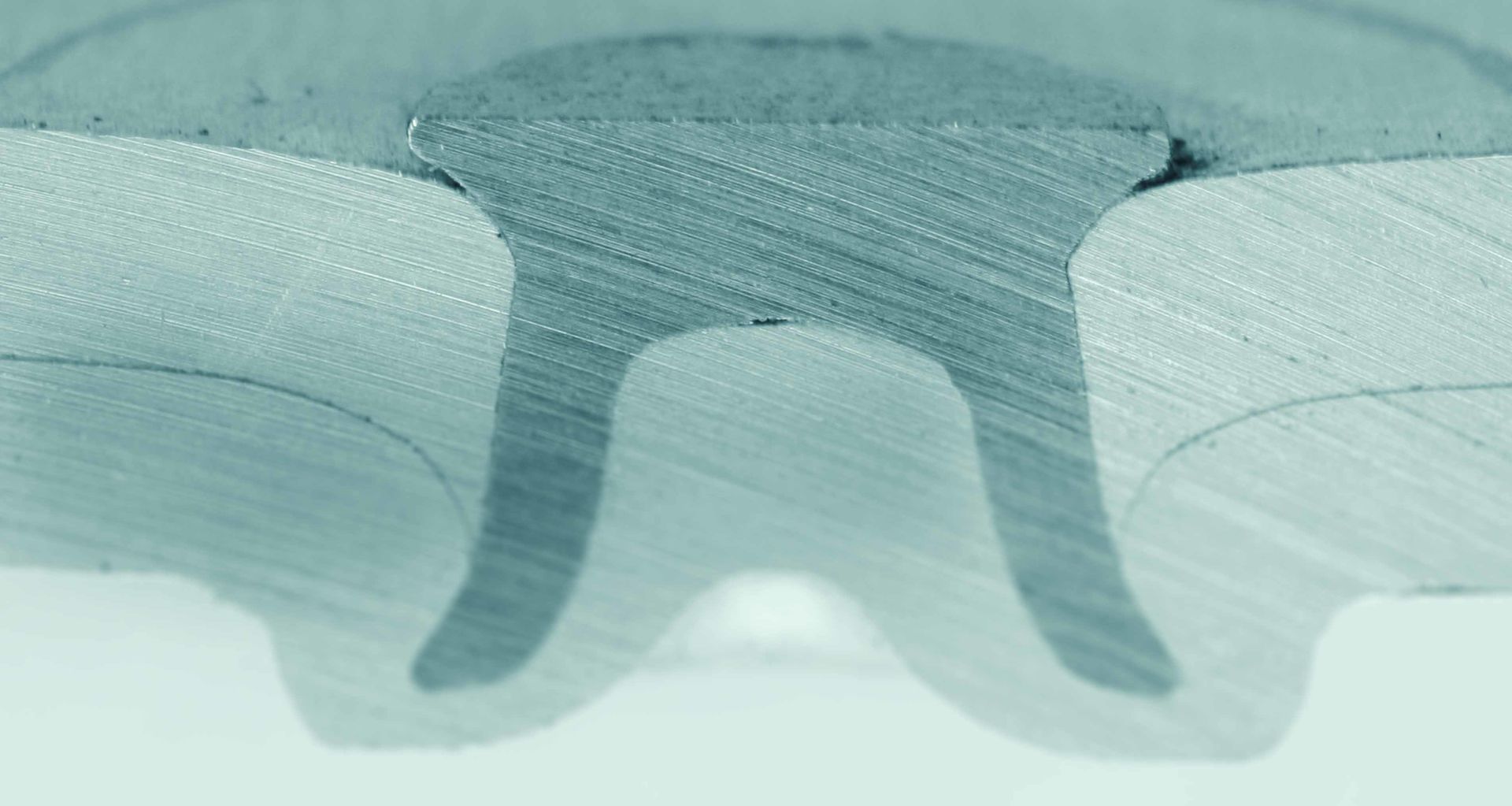

The ECKOLD self-piercing riveting machines are designed for the setting of C-geometry semi-tubular self-piercing rivets. Customised machines for manual riveting are primarily used in pre-series and small series production. Automated self-piercing riveting systems from ECKOLD are the preferred option for series production.

Multi-function unit MFG 500/150 E – The machine for every situation.

Clinching, self-piercing riveting, punching, pressing-in and embossing: The MFG 500/150 E is a universal C-shaped stationary machine designed for sheet metal ulilising industries. In respect to working with sheet metal and profiles in aluminium, steel or stainless steel many demands are realized. However a new machine is not needed every time but merely an appropriate tool holder is inserted and the machine is ready for a further task. You can also choose from standardised tool holders or a custom-manufactured tool holder according to your needs. You can find further information in our brochure which is available for downloading below.