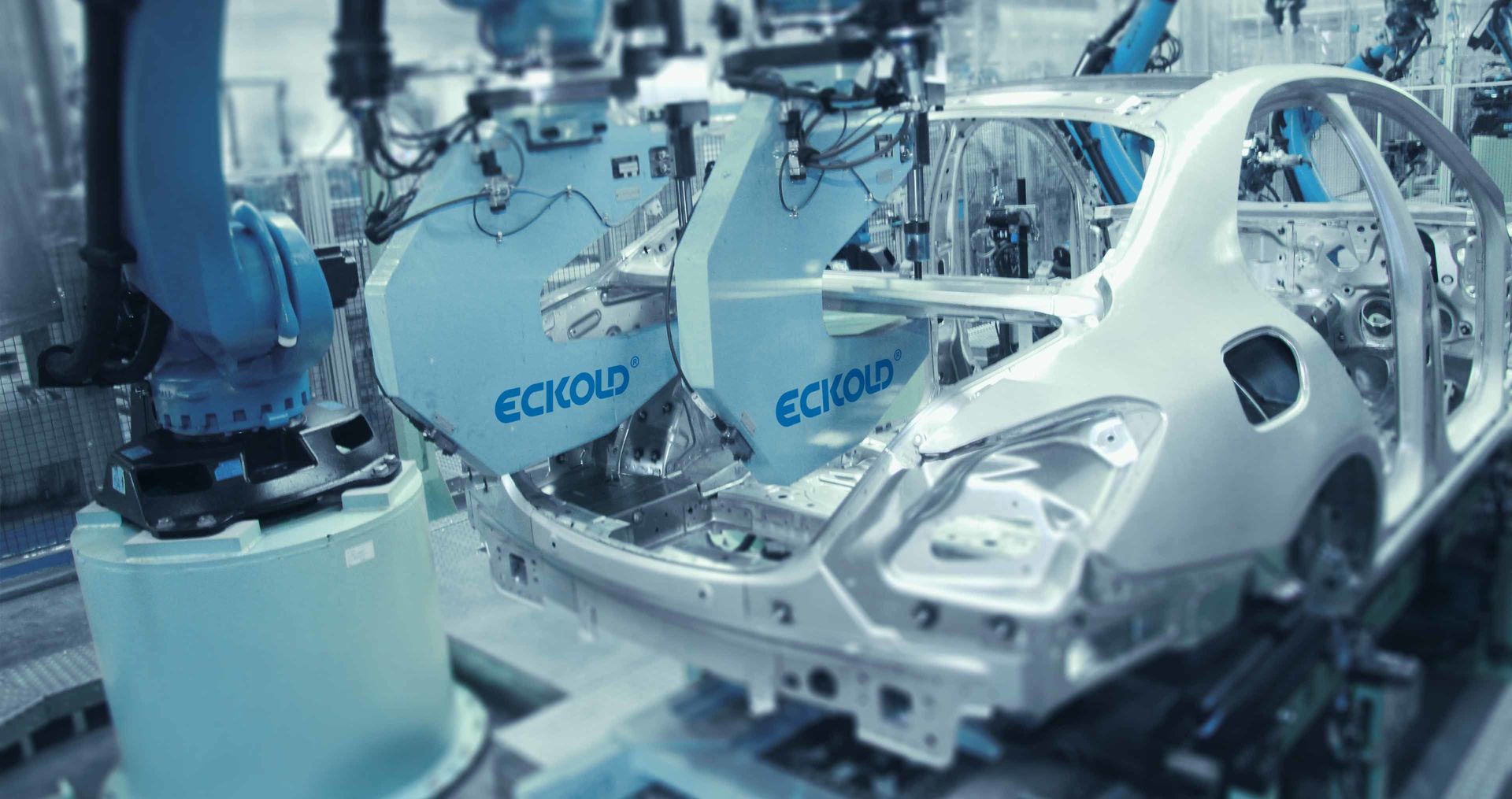

As the demand for automated and faster production solutions increases at an ever faster pace, the automotive industry continues to be an innovation driver. Today, machines must be smart, flexible and able to work at high speed, as the life cycles of individual models have become ever shorter and manufacturers need to reduce their time-to-market phases. While others are still stuck in planning, ECKOLD is already offering such solutions!

As a top service provider of the automotive industry, we offer you equipment and machines featuring highly intelligent control technology, and develop customised solutions for your specific production requirements. ECKOLD provides smart solutions for all connections between car body parts and other vehicle components! Take advantage of our know-how and avail of the many customer benefits on offer from ECKOLD.

ECKOLD sets new standards in automotive production

We boost efficiency in car production! With ECKOLD machines and techniques, car manufacturers can not only save costs, but also enhance work safety and quality thanks to standardised, online-monitored machines. ECKOLD covers everything from clean and sustainable clinching to laser-guided embossing and punching of sheet metal – and its machines keep what they promise:

- More efficient car production thanks to shorter process times

- Automated car production with standardised, online-monitored machinery

- Rugged machine technology designed for low maintenance and minimum downtimes in production

- Flexibility in car production with hybrid joining and mixed joining

- Precision car production thanks to advanced ECKOLD technology

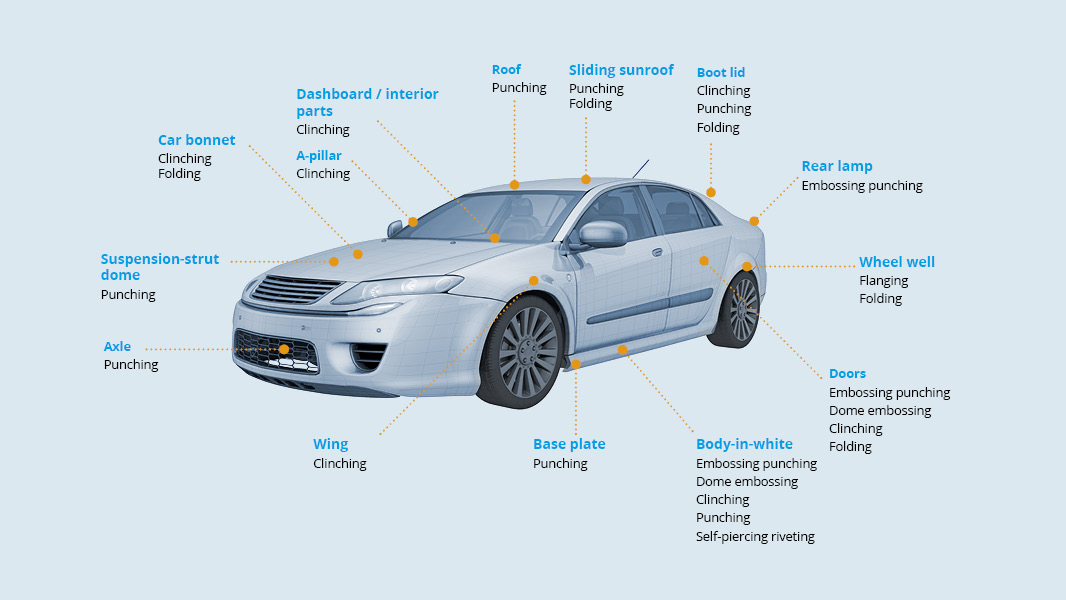

Which technology for which car body part?

Car manufacturers around the globe use our techniques in series or pre-series production of car bodies and automotive components. Clinching is primarily used for the construction of mounted parts such as car bonnets, wings and boot lids. The technique is also used for the joining of mixed materials. ECKOLD portable self-piercing riveting systems are designed for universal use. They come with short cycle times and can be positioned at components that are hard to access, thus covering a range of applications in pre-series and small series production. ECKOLD punching machines cater not only for the production of round or shaped holes, but also for notching and shearing. They can therefore be used to machine virtually any car body or undercarriage. Machines for embossing and dome embossing are primarily used for headlight and rear light sections, as well as for hinges, door stops and lock mounts. The ECKOLD Kraftformer is a universal forming machine mastering even tricky tasks – quickly, precisely and with excellent reproducibility. To enlarge wheel wells, we recommend the ECKOLD wheel flanging devices. Hatches, doors, roof openings and wheel wells can be produced with ECKOLD folding technique, which is not only extremely efficient but also cost-effective.

From bonnet to boot – ECKOLD clinching

It was in the 1980s when ECKOLD introduced clinching to the market. Initially, the company used the German term "Druckfügen" or press-joining to describe its innovative technique. Soon afterwards, ECKOLD launched a number of machines for industrial clinching, a milestone in the automotive industry and other sectors. With clinching, metal components are joined in a single step – without damage or deformation. There is no need for preparation or reworking such as pre-punching, deburring or grinding. Where other joining techniques reach their technical limits, clinching is often still an option, for instance for the permanent joining of steel and aluminium workpieces in lightweight constructions. Clinching is also the perfect solution for hybrid joining by means of clinched and glued joints where clinching serves as the initial fixing method. In the automotive industry, ECKOLD clinching has established itself as a standard technology for the joining of components, and the technique is constantly being developed and improved by the company that has first brought it to market. And we will continue to come up with new machines! In recent times, we launched exceptionally efficient servo motor-driven clinching systems for large-series production, which are already revolutionising automotive production.

Clinching, punching, embossing punching, self-piercing riveting, forming – for every vehicle model and car body part, manufacturers must find the most suitable technique for efficient production. For many decades, renowned automotive companies and their suppliers have been relying on innovative technologies and machines from ECKOLD. ECKOLD has been serving the automotive industry for more than 80 years with advanced solutions and tools for both manual and automated production.

By opting for ECKOLD, automotive manufacturers and suppliers know that they get the most advanced solutions. That is why we are the trusted partner of leading companies in Germany and around the globe. In addition to innovative products and technologies, we offer a bundle of excellent services as well as custom-engineered tools and machines for your specific production needs. We would be delighted to design a solution that exactly meets your requirements, and help you commission your new ECKOLD machine. As a competent and reliable service provider, we will of course be there for you whenever you require our assistance.