Perfect results can however only be achieved, if every single detail is optimised for efficient machining, accurate embossing and smooth surfaces. In many stamping plants, large car body components such as bonnets and doors are no longer produced with embossed sections and pre-punched holes, as these are now added at a later stage along the assembly lines, using special tools for the various car models. This means that the prefabricated car body parts can be stacked more densely in containers for shipping to the assembly plants.

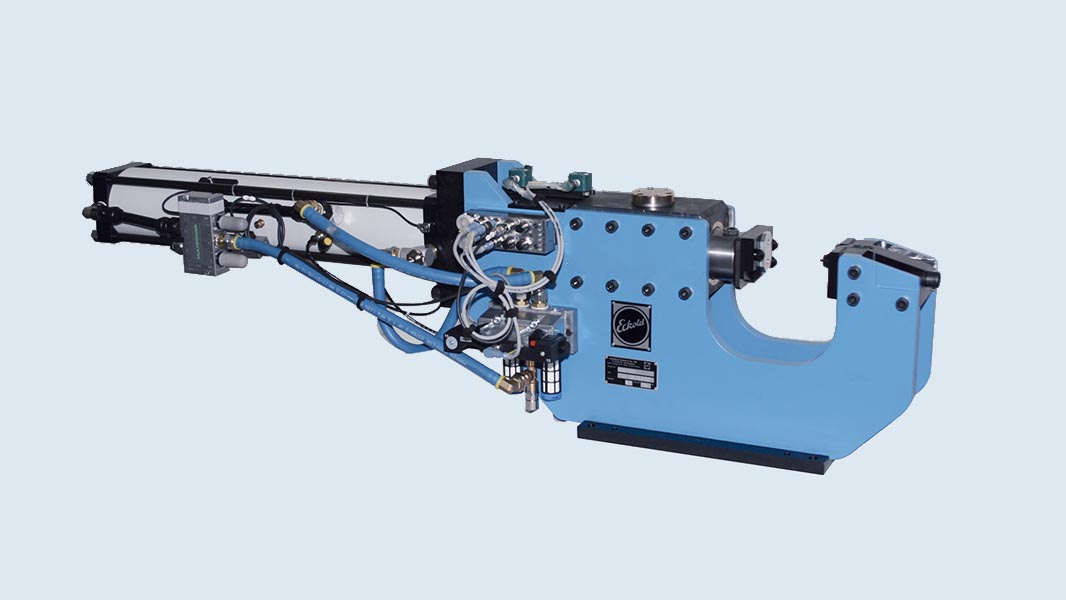

Domes produced with ECKOLD machines make sure that there is only a minimum offset between the securing screws and the surrounding metal. ECKOLD machines can produce two or even three domes in a single process. Our dome embossing machines are suitable for both single and double sheet steel or aluminium parts and come with a hydro-pneumatic or servo motor drive system. With our machines, domes can be embossed without preliminary holes (even when combined with final hole punching for a defined diameter).

Advantages of dome embossing machines

- Embossing and punching in a single stroke

- No need for preliminary hole punching

- Accurately defined final hole diameter

- Suitable for single-layer and double-layer sheet metal

- Control and process monitoring visualisation (optional)

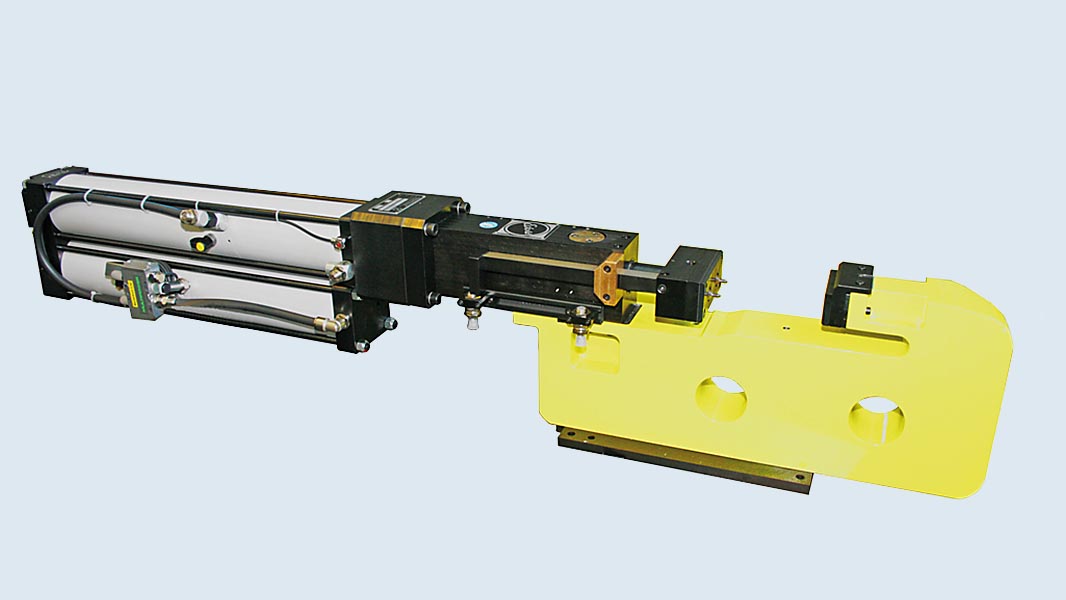

- Wide range of frame designs

- Not limited to specific car component

- Designed for robot control

Technical data

| Parameters | single-layer | double-layer |

|---|---|---|

| Embossing depth | 2.50 - 5.60 mm | 2.20 - 2.80 mm |

| d = dome | 13.80 - 19.60 mm | 13.00 - 14.00 mm |

| d = preliminary hole | 3.70 - 5.80 mm | 3.80 - 5.60 mm |

| d = final hole | 5.80 - 7.60 mm | 5.80 - 8.50 mm |

| Sheet thickness | 0.65 - 0.90 mm (steel) | (ss) 0.75 - 0.80 (steel) (ss) 0.75 - 1.50 (Al) (ms) 0.80 - 1.00 (steel) (ms) 0.80 - 1.50 (Al) |

| Tensile strength | Steel (Rm = 400 N/mm2) Aluminium (Rm 250 N/mm2) | Steel (Rm = 400 N/mm2) Aluminium (Rm 250 N/mm2) |

Dome embossing with recessing punch

Machines for dome embossing with a recessing punch use special frame inserts fitted with protruding punches. This means that mirrored components can be produced with a single embossing frame tool insert. In most plants, the workpieces are handled by robots. This has the great advantages that a single embossing frame is sufficient to machine both sides of the vehicle.