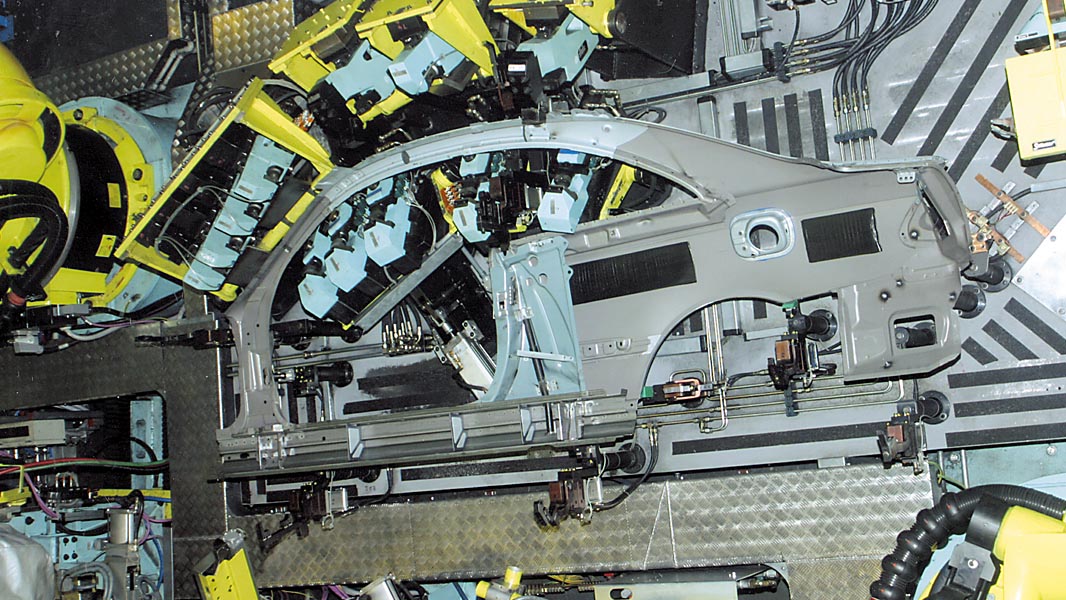

Automated punching plants are particularly economical for large quantities, offering excellent process safety. They are therefore very popular with automotive component suppliers and manufacturers of white goods. The ECKOLD range of punching machines includes automated punching units as well as portable and hand-held tools, thus catering for virtually any punching task.

As an innovative partner of the industry, we act as a full-service provider, offering advice, customised designs and a comprehensive after-sales service. We also assist you of course in the assembly and installation of your machine on site and the training of your personnel. We also provide user support and maintenance services for punching machines. After a detailed evaluation of your punching task, we devise a solution that is not only economical but also perfectly adapted to match your requirements and workpiece specifications.

Special machines

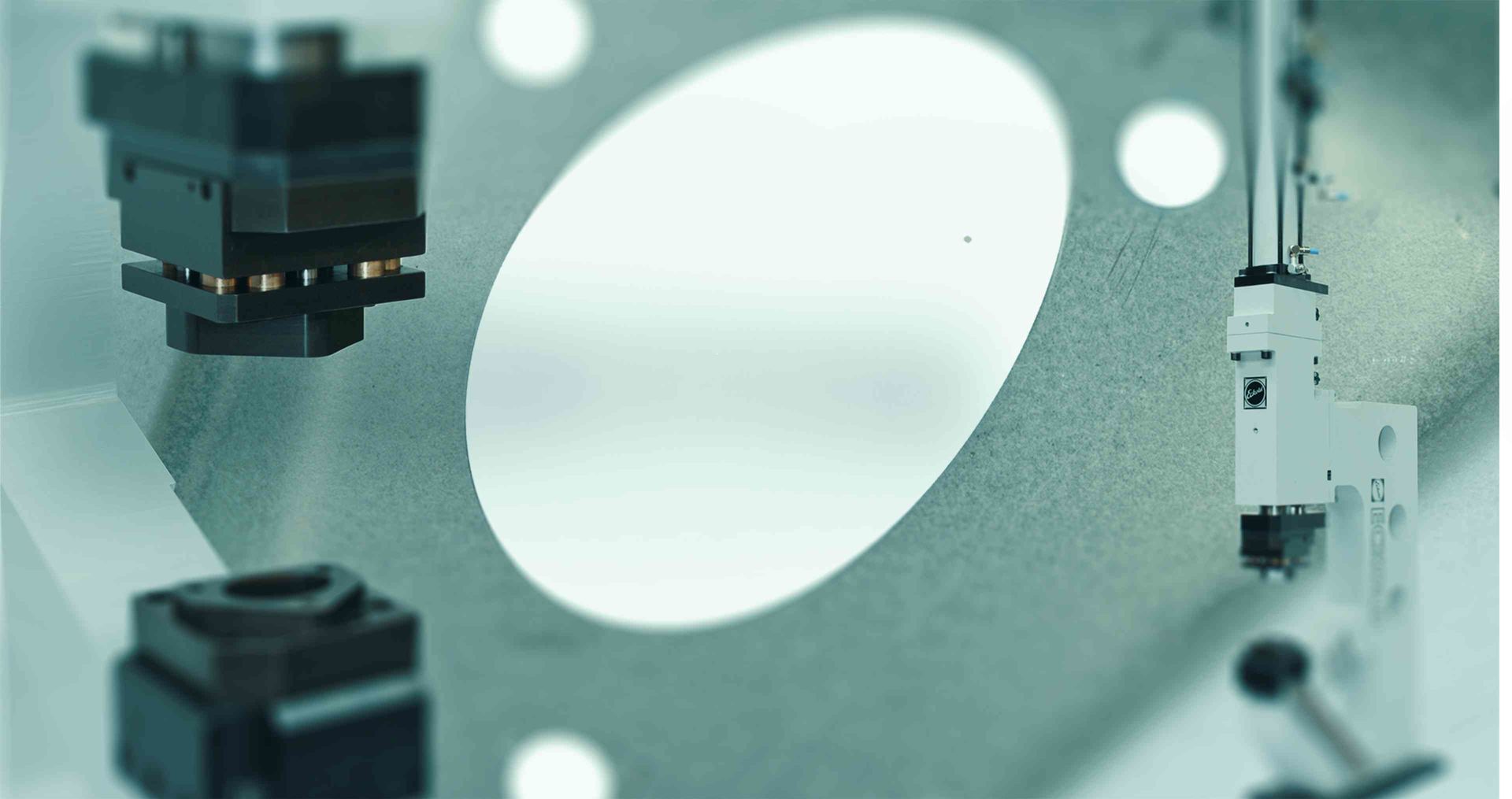

From our experience in punching technology, we know that standard solutions cannot meet all requirements. That is why we are constantly expanding our range of machines and services with new smart and extra efficient devices and techniques. For manufacturers, we offer portable devices and components for integration into large production plants, handling components for industrial robots and complete punching plants. ECKOLD punching machines can be used for many different applications – from notching and punching round or shaped holes to shearing/cutting multiple sheet layers. For its punching machines, ECKOLD offers a range of special drive options. Choose from hydraulic, hydro-pneumatic, pneumatic and electrical drive systems. For more information, refer to our new brochure for punching technology available for download.

Multi-function unit MFG 500/150 E – The machine for every situation.

Clinching, self-piercing riveting, punching, pressing-in and embossing: The MFG 500/150 E is a universal C-shaped stationary machine designed for sheet metal ulilising industries. In respect to working with sheet metal and profiles in aluminium, steel or stainless steel many demands are realized. However a new machine is not needed every time but merely an appropriate tool holder is inserted and the machine is ready for a further task. You can also choose from standardised tool holders or a custom-manufactured tool holder according to your needs. You can find further information in our brochure which is available for downloading below.