When designing a new building, metal construction specialists, building planners and proprietors need to choose suitable garage doors, façade features, roller shutters, windows, doors and conservatories. Sheet metal and profiles are key elements of such structures – not only because of their load-bearing function but also with regard to their durability and visual impact. Given the ever changing requirements in building construction and renovation, small and large manufacturers depend on innovative production processes.

At a time where skilled workers are hard to find, automated solutions have become even more attractive. Today, energy efficiency, cost factors, the availability of parts as well as the protection of resources and our climate are major considerations when choosing a new production method. For manufacturers of garage doors, metal façade elements, roller shutters, windows, doors and conservatories, solutions from ECKOLD offer many distinct advantages.

ECKOLD sets new standards in metal construction

Improve the efficiency of your production methods for garage doors, façade elements, roller shutters, windows, doors and conservatories! ECKOLD's machines for forming, punching, self-piercing riveting or joining by means of its innovative clinching technique enable manufacturers to produce at lower costs. In addition, the sturdy design of ECKOLD machines and their long service life guarantee consistent, high-quality machining results over many years. The ECKOLD solution portfolio for cost-effective joining, punching and forming of sheet metal and profiles ranges from hand-held portable pliers and battery-powered machining frames to stationary multi-function units and semi-automated production plants.

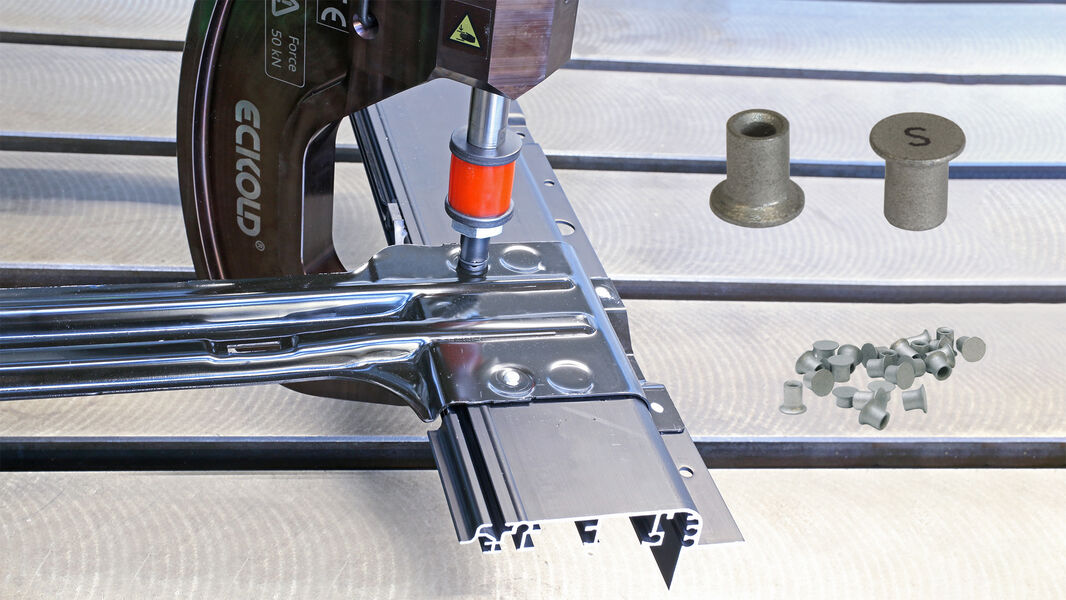

Clinching

It was in the 1980s when ECKOLD introduced clinching to the market. Initially, the company used the German term "Druckfügen" or press-joining to describe its innovative technique. Soon afterwards, ECKOLD launched a number of machines for industrial clinching, a milestone in the sheet metal machining industry and other sectors. With clinching, metal components are joined in a single step – without damage or deformation. There is no need for preparation or reworking such as pre-punching, deburring or grinding. Where other joining techniques reach their technical limits, clinching is often still an option, for instance for the permanent joining of steel and aluminium workpieces. As there is no need for additional fastening elements, clinching is particularly suitable for lightweight constructions. Among manufacturers of gates and doors, ECKOLD clinching has established itself as a preferred technology for the joining of components, and the technique is constantly being developed and improved by the company that has first brought it to market.

Advantages of clinching

- No thermal effect on joint / No hazardous gases and fumes

- No need for preliminary surface treatment or subsequent preservation work

- No additional material required

- No need for auxiliary fixtures such as screws or rivets

- Suitable for painted and coated sheet metal

- Suitable for the joining of different materials and/or workpieces of various thickness

- Three-layer joining (S-DF)

- No increased corrosion at clinching points / cost-effective

Self-piercing riveting

Self-piercing riveting with the ECKOLD technique uses specially designed rivets. The company offers everything from manually operated devices and stationary machines to self-piercing riveting systems designed for integration into automated production lines. In addition, the ECKOLD standard machine range includes battery-powered hand-held and stationary multi-function units that can be easily configured for specific metal and façade construction tasks.

Forming

ECKOLD Kraftformers and Handformers are designed for the cold forming of sheet metal, tubes and profiles. They are high-precision, low-noise units for chipless machining. On a single Kraftformer, you can for instance bend profiles, form sheet metal elements, produce new parts, complete repairs or cut intricate contours. Many decades ago, ECKOLD was the first manufacturer to offer machines for customised sheet metal forming, and is still one of the leading suppliers in this field. For its machines, ECKOLD offers a wide range of tools designed for quick exchange and installation. This ensures high machine utilisation and versatility. The intelligent technology from ECKOLD is unique in the world.

Wherever metal needs to be machined – be it in small workshops, on construction sites or in industrial production plants – ECKOLD is never far away. Thanks to the unique ECKOLD technique and the unrivalled versatility of its machines, ECKOLD machines are in high demand all over the world. Where sheet metal and profiles need to be stretched, shrunk, domed, planished, straightened or formed for metal constructions, ECKOLD machines are generally the first choice.

Punching

From our experience in punching technology, we know that standard solutions cannot meet all requirements. Our systems have been tried and tested in a wide range of applications, and our customised punching machines are in operation all over the world. For manufacturers, we offer portable devices and components for integration into large production plants, as well as handling units for industrial robots and complete punching plants. ECKOLD punching machines can be used for many different applications – from notching and punching round or shaped holes to shearing/cutting single and multiple sheet layers.

As an innovative partner of the industry, we act as a full-service provider, offering advice, customised designs and a comprehensive after-sales service.

With a comprehensive machine concept ranging from hand-held portable devices and stationary machines to customised units and plants, ECKOLD offers solutions for virtually any metal construction task. Within the ECKOLD product range, you will find a sheet metal machining solution that perfectly suits your requirements – be it for manual joining with portable tools, or automated series production.

For many decades, leading metal construction companies, roller shutter manufactures and HVAC specialists have been relying on the innovative techniques and machines from ECKOLD who has been serving the sheet metal machining industry for more than 85 years and continuously develops new advanced machines and tools.

We offer solutions for strong and durable connections.

![[Translate to Englisch:] Eckold Technologien für Garagentore, Fenster, Türen, Wintergärten](/fileadmin/Redakteur/Branchenloesungen/Garagentore-Fassaden-Rollladen/Garagentore-Fenster-Tueren-Header.jpg)