27.07.2021

Berlin Palace dome in good form with ECKOLD Kraftformers

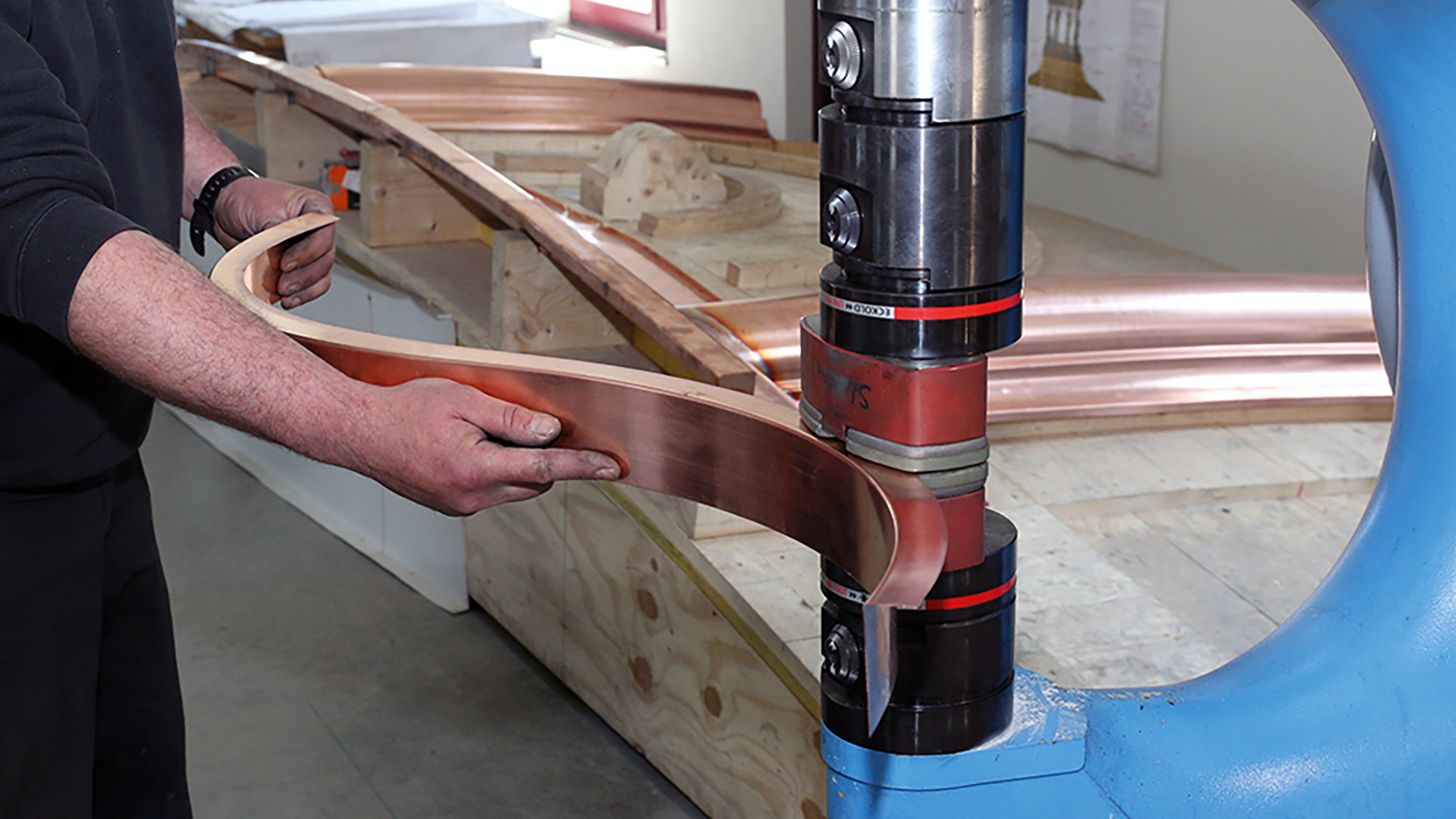

It is worthy of note that machines produced by ECKOLD once again played a central role in building this prestigious structure. The dome, which is visible from a great distance, consists of countless single copper elements that were formed by means of Eckold Handformers and Kraftformers. These sheet-metal forming machines are used primarily for the manufacture of metal sheets and profiles that require custom shaping and adaptation. When one looks at the new “Berlin Palace”, also known correctly as the “Royal Palace, it is impossible to miss the 70-metre copper dome of the west wing.

The Thuringian company “Metallart Taubert” in Greiz is responsible for this master work of craftsmanship, which involved building the complex copper dome and covering it with a copper shell. The process was developed over a period of years. After the planning was completed and the ink on the perspective drawings had dried, the focus turned to the question of practical implementation. On 14/07/2017 the roofers and sheet-metal workers from Thuringia received a live demonstration of the capabilities of Eckold Kraftformers in St. Andreasburg as the birth of a possible solution for the numerous complex tasks ahead. As master roofer Strezl put it: “That’s exactly what we need!”

A temporary Kraftformer was promptly delivered to Greiz to bridge the time until delivery of the actual machine, Kraftformer KF 470 with an extensive array of tools. These included diverse LFA and LFR forming tools for shrinking and stretching, which feature special adhesive plastic contact surfaces to prevent damage to the copper sheets during forming. This made it possible to achieve outstanding results for the complex forming tasks without leaving any unsightly marks on the soft materials.

After a short training phase, numerous large elements were manufactured in Greiz on the basis of wooden moulds and prepared for installation; this second phase lasted well into the year 2018. Keeping track of the large number of elements needed and planning production efficiently was more like playing the lottery at times. But the sheet-metal workers continued under the supervision of the proprietor André Taubert, and set out for Berlin the same year, to start work on the substructure for the dome. For the next two years, the height of the Thuringians’ workplace – initially 35 metres – increased steadily as the dome gradually reached its final height of 70 metres.

The project required a great deal of precision and flexibility on the part of the Greiz-based company. At dizzying heights the employees used the Eckold Handformers and Handpliers, which are likewise equipped with plastic-coasted tools, for final adjustments.

The result speaks for itself – as do the dimensions of this structure and the artisan skills required to build it. As machine manufacturers we are very proud to have been a part of the solution.

For more interesting information about the Berlin Palace, visit

https://berliner-schloss.de/en/

The virtual vision from the year 2015 provides an interesting and informative overview. This impressive 3D animation, which shows the dimensions of the structure, is available here:

https://berliner-schloss.de/neues-schloss-humboldt-forum/das-neue-schloss-im-film

Learn more about our Handformers and Kraftformers here.

Comments are disabled for this post.

0 Kommentar