25.10.2021

New materials are conquering the automotive sector - ECKOLD tests their feasibility

Our mobility is changing. Cars have to be light - which reduces fuel consumption and CO2 emissions - but they also have to be sturdy to protect the occupants and get them safely to their destination. Reducing weight also plays a major role in the construction of electric vehicles, as this can increase the range, for example. This is why the use of lightweight materials is still a key issue in automotive construction. Alongside aluminium, magnesium and fibre-reinforced plastics, for example, ultra-high-strength steel or aluminium materials are becoming indispensable in lightweight construction. But can they be formed and joined just as well as the materials that were used before?

This is where ECKOLD’s technical test field comes into play. Renowned automotive manufacturers from Germany have relied on our development engineers’ expertise for decades.

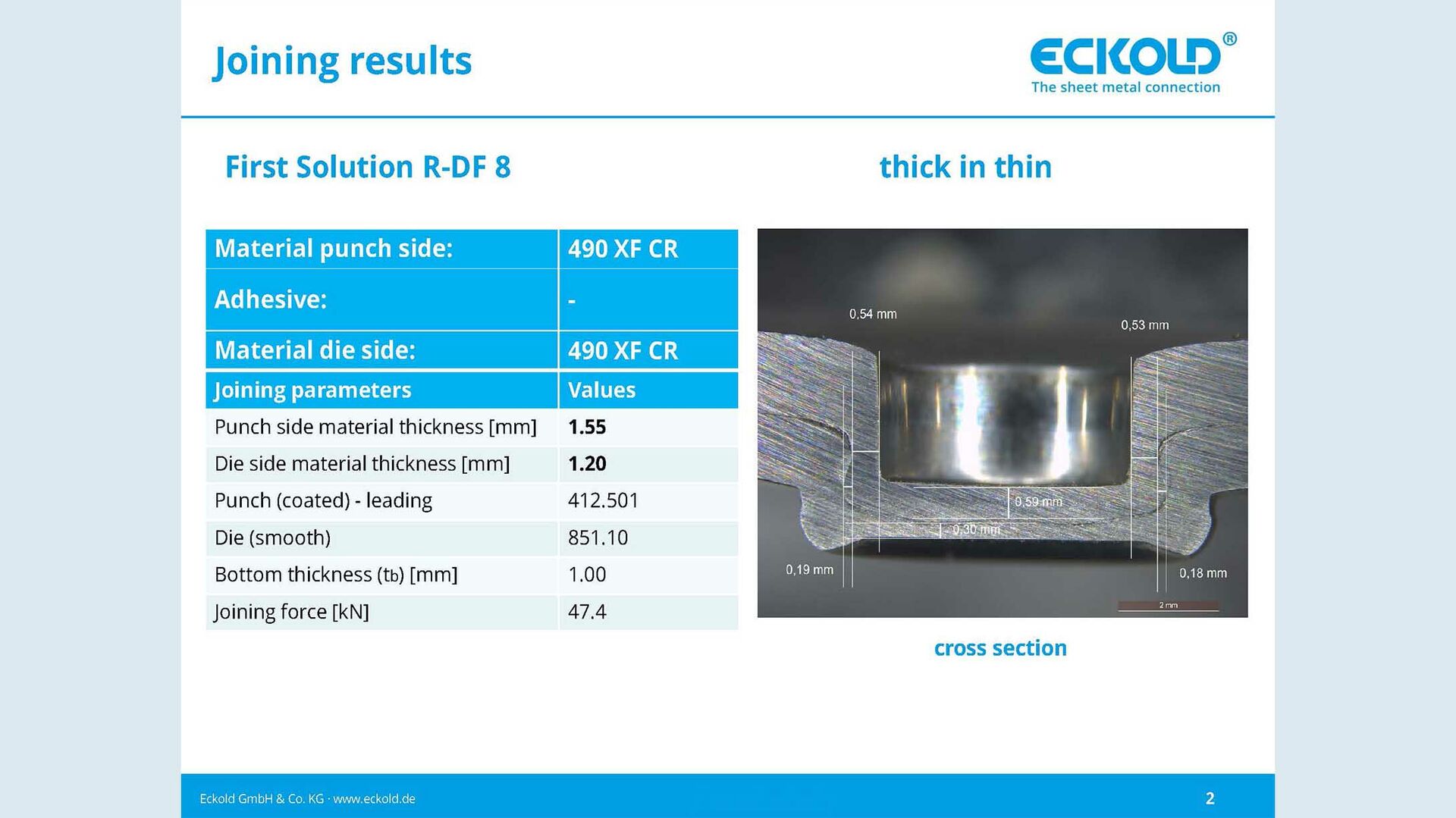

In the technical test facility, tools and processes are adapted to new materials and refined. As a result, innovative solutions are created in cooperation with our customers. These solutions are then used in production facilities all over the world. We do this for joining technology, like clinching, shear clinching, self-piercing riveting and press-fitting of functional elements, and forming technology, like extrusion embossing, embossing & punching or shear cutting.

Our feasibility studies for the design of the tools and corresponding test runs already establish the technical feasibility of the planned customer project in advance.

In most cases, we receive an enquiry from the customer; if new materials are involved, then we also often receive components from the project in question and we use them in the tests. We also have a sample database where our specialists can find what they’re looking for in many applications - this database contains several thousand sample part combinations with the corresponding joining tools. We also stock common sheet metal materials and thicknesses, so we can carry out a quick feasibility analysis.

The samples are first given a separating cut, and then the interface is ground. The microscope takes a picture of the interface – called a polished cut image. The polished cut image is then precisely measured and evaluated using appropriate software. The bond strengths such as shear strengths, top strengths or peel strengths are determined with the help of a tensile testing machine.

Are you also working on an exciting project? As a matter of course, we don’t just offer our services for the automotive sector. We look forward to your enquiry!

Comments are disabled for this post.

0 Kommentar